BEARINGLESS PUMP | LEVITRONIX

|

A New Standard for Magnetically Levitated Centrifugal Pumps

Levitronix has developed a Bearingless Centrifugal Pump for the semiconductor industry based on proprietary magnetic levitation technology. With the Levitronix technology, a pump rotor is suspended and driven by the magnetic field of a motor/bearing stator through the wall of the pump housing without mechanical contact. A signal processor-based electronic control unit allows precise regulation of the speed, pressure or flow rate. The Ideal Pump for Single Wafer Processing Levitronix pumps operate in a pulse-free mode making them ideally suited for use in single wafer wet-processing tools. A single pump can feed several process chambers and produce a constant, homogenous flow on the Wafer. Electronic control helps to maintain the flow at a precise, constant rate independent of the state of a filter. Our electronic control system can also be used to diagnose the status of a filter and indicate when it needs to be exchanged. Levitronix pumps are much smaller than bellows or diaphragm pumps with comparable flow-rates without the need for pulse-dampers. This helps to build your new tool smaller than ever before. The Ideal Plating Pump Due to its unique design, the Levitronix pump has no bearings, valves, or membranes, which can plate out when used in plating processes. Levitronix pumps are the best choice for the following electrochemical plating (ECD) processes: 1. Gold ECD 2. Copper Damascene 3. Patterned Copper ECD 4. Permalloy ECD (GMR heads) 5. Nickel ECD (packaging, MEMs) 6. Solder ECD (bumping) The Ideal Pump for CMP Slurries and Other Sensitive Fluids Levitronix is a leading expert in low shear pump design. The company's medical blood pumps have been shown to cause minimal damage to the blood cells as demonstrated by a low rate of hemolysis (red blood cell destruction). The hemolysis rate associated with the Levitronix blood pump is approximately 50% of the industry standard device, and is also less than any peristaltic pump. The same low-shear blade design has also been applied to our high-purity fluid pumps. The low-shear blade design, combined with avoidance of small fluid gaps, translates to lower shear force acting on the fluids and prevents the creation of hot spots. By generating continuous pulseless flow, the Levitronix pump is ideally suited for pumping sensitive fluids such as CMP slurries. Particle distribution, as well as zeta potential, has been shown to remain constant over 3000 tank turnovers (detailed report available). For the same reason, the Levitronix pump creates fewer bubbles than bellows pumps in sensitive fluids like Triton-X 100 solutions. DETAIL Designed for Highest Purity The Levitronix BPS pump systems are designed for high-purity fluid applications where low particle shedding and metal contamination are required. The pump heads are made from high-purity fluorocarbon resins (PTFE, PFA, ECTFE, PVDF) and can be easily |

cleaned or exchanged resulting in less down time and lower maintenance costs.

Chemical Resistant Design Each bearingless motor is completely potted, the housing is coated with ETFE and all cables are FEP jacketed. As a result, our systems are impervious to aggressive chemicals and can be utilized even in submersible applications. Extremely Low Particle Generation An important advantage resulting from contact-free levitation of the rotating impeller is that the system can be operated with extremely low particle generation. Tests conduced by an independent test laboratory show that particle generation of a Levitronix pump during operation is significantly less than that of a bellows pump of comparable hydraulic performance (detailed report available). Extremely low Metal Contamination The wetted components of Levitronix pumps are fabricated from ultra-high purity fluorocarbon materials. Independent tests have verified that the area normalized surface metal contamination is well below industry standards. Since other leading high-purity pump manufacturers use comparable high purity fluorocarbon materials, and process these materials with the same high degree of care, the area normalized surface metal contamination values for their products match those of the Levitronix pump. However, since the wetted surface area of a Levitronix pump is about 30 times smaller compared to a typical bellows pump, the total metal contamination which bellows-type pumps introduce into a system is 30 times higher compared to a Levitronix pump. Hermetic Rotor Encapsulation In order to assure minimal metallic contamination over time, the rotor-magnet is encapsulated and protected by two polymeric layers. The first layer is a proprietary coating with extremely low permeability, and the second is a ultra high-purity PFA layer to enhance chemical resistance. The rotor-magnet is then embedded within the high purity fluorocarbon body of the impeller. Electronic Control and Interfacing Levitronix pump systems are digitally controlled with a powerful digital signal processor (DSP) and incorporate multiple analog and digital interface options. This allows easy interfacing to PLC systems, host computers and systems controllers. Our systems are also designed to interface with a variety of flow, pressure, temperature, viscosity and fluid density sensors. Levitronix provides software modules which allow closed-loop flow control, pressure control and process control systems without additional hardware. Since each system is equipped with sensors for speed, torque and rotor position, multiple process parameters can be monitored or controlled without the use of external sensors. Levitronix provides extensive engineering support to implement these and other features into your process. Electronic control features 1. Continuous flow or custom defined flow patterns 2. Precise electronic control of flow rate or pressure without throttle valves 3. Better process control, fewer system components, higher systems efficiency 4. Monitoring of fluid viscosity 5. Monitoring of filter life in a flow control loop |

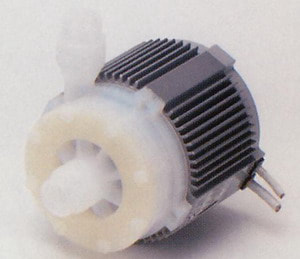

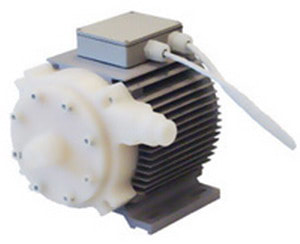

Bearingless Pump System BPS 2000Model: BPS 2000

SPECIFICATION High Pressure Profile Max. Differential Pressure: 6.9 bar (100 psi) Max Flow: 80 liters/min (21 gallons/min) Wet Materials: PFA, PFA Fittings: Flaretek 1" High Flow Profile Max. Differential Pressure: 4.2 bar (61 psi) Max. Flow: 140 liters/min (37 gallons/min) Wet Materials: PFA, PTFE Fittings: Pillar 1” Female Max. Liquid Temperature: 85°C (185°F) Supply Voltage: 1 x 200-240 V AC /3 x 200-240 V AC |